The First Maintenance Application Production Line Integrating Digital and AI Technology in Ship Repair Industry was Put into Operation in IMCZY

2024-06-15

To explore the future development mode of the ship repair industry, IMCZY has successfully constructed the “Future Ship Maintenance IMCZY Silicon Valley” and the application production line, following a prolonged period of continuous efforts and technological accumulation. This initiative integrates the concepts of digitalization, intelligence, environmental sustainability, and low-carbon emissions, and has been operational for several months. This innovation can not only inject new impetus into the high-quality development of the ship repair industry but also lay the foundation for cultivating a new quality productivity industry. It further reveals the practical application of cutting-edge technology in the future ship repair industry.

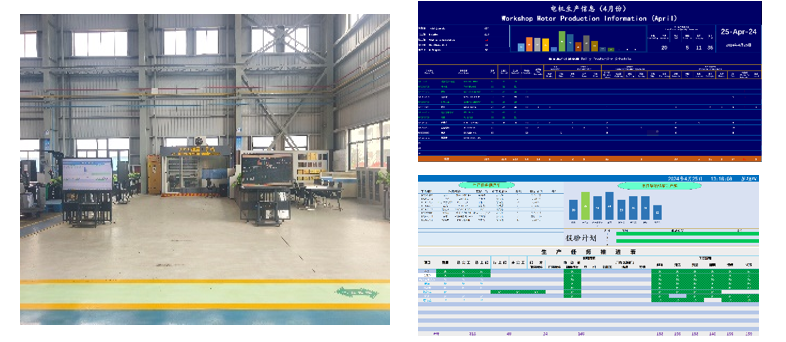

Take Internet of Things (IoT) and info-digital technology as the core, and aided by a full-coverage 5G network, customers and staff can log onto the digital production management platform to visually experience real-time scenarios of ship's mechanical and electrical equipment maintenance.

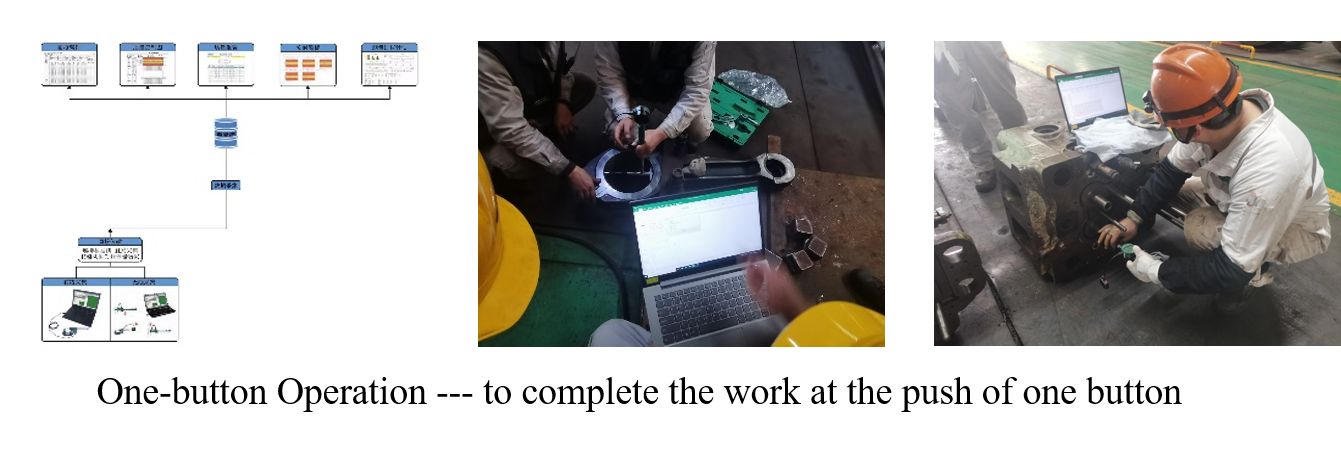

The SPC (Statistical Process Control) manager, by discarding the traditional method of component measurement, enables wireless data collection and transmission from inspection gauges to PCs, thus providing more accurate and timely information and data support for the decision-making process related to maintenance schemes.

For component management, the “Future Ship Maintenance IMCZY Silicon Valley” has established a parts and materials digitization management center. Each vessel utilizes the single shelf management mode, ensuring that all parts are labelled and tracked under the digital inventory management system. This innovation has significantly improved the efficiency and accuracy of component management.

Furthermore, the automatic valve grinding machine independently developed by IMCZY has made a breakthrough in the two-stroke and four-stroke diesel engine cylinder head repair bench. This innovation discards the traditional manual grinding method and enables automated operation, thereby significantly enhancing working efficiency and quality.

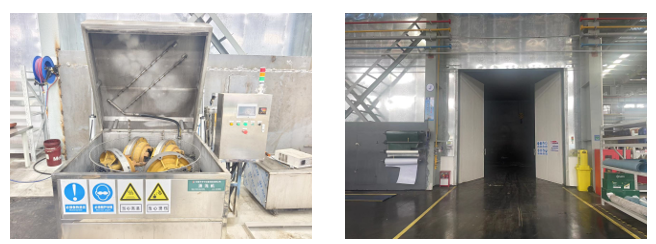

In the component cleaning center, IMCZY has established a high-pressure cleaning room and automatic rotary spray cleaning machine to effectively meet the cleaning requirements of both large-sized workpieces and small parts. Furthermore, an intelligent cleaning robot, ready for duty, can carry out fully automated cleaning procedures for large-sized parts through the using of scanning and imaging technology. This transformative shift workers from dirty, messy, and noisy working environments and enhances their sense of well-being.

The utilization of CNC inner &outer surface fusion covering machine streamlines the piston rod and shaft repair process while eliminating the necessity for surface chrome-plating. This not only reduces environmental pollution but also significantly shortens the repair cycle. This innovative application has been widely recognized and praised by owner.

The “Future Ship Maintenance IMCZY Silicon Valley” is committed to innovating efficient and high-quality work methods, and continuously improving the levels of mechanization, automation, digitalization, and intelligence. IMCZY and its partners have jointly developed a fully automatic assembly and commissioning production line for ship motor repair, which has significantly improved working accuracy, safety, and efficiency.

The cryogenic workshop is specially designed for the repair work of LPG & LNG equipment, and has successfully carried out equipment repair tasks for numerous LPG vessels.

As a forefront enterprise in green development within the ship repair industry, IMCZY shoulders the social responsibility and mission of the era, and is boldly leading the way in integrating green, low-carbon, digital, and intelligent concepts. The “Future Ship Maintenance IMCZY Silicon Valley” is diligently exploring, pioneering, and establishing the path towards ESG sustainable development in the global ship repair industry.