The Innovative Road of Bulbous Bow Modification

2023.8.20

On 23rd July, vessel with a new bulbous bow nose slowly left IMC Zhoushan shipyard and started her new journey. The retrofitting of bulbous bow is an important way for the vessel to reduce fuel oil and carbon emission, and the modification of this "new nose" is the project that independently completed by our company in the process of prefabrication of bulbous bow segments.

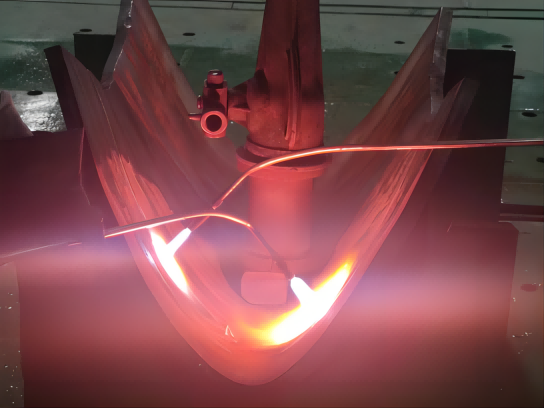

The first challenge of bulbous bow construction is to process the outer plate. The unfolding and processing of the outer plate has always been a difficult point for ship repairing companies in the bulbous bow refitting project. Facing the challenge that our company constructs the bulbous bow for the first time, the structural production line grasps the nettle, work together, and overcome difficulties positively. After several tests, pieces of outer plate formed a fine curve under their beautiful firelight.

Next is the challenge of precision control. In order to achieve the goal of nonredundant closing in dock, precision control is required at the beginning of material cutting. The second step is the outer plate by line heat forming and Inverse linear manufacture of steel structure. And in the third step of precision control is the sectional prefabrication and erection, utilizing the total station to measure each principal dimension to control the assembly accuracy in advance. After the final overall measurement of sections, the total station was well used to draw the cutting line and do allowance cutting for preparing the nonredundant joint in dock.

This vessel entered the dock on 13th July and left on 20th July, completing the work of entering and exiting the dock, cutting the old bulbous bow, installing the new bulbous bow, welding, pressurizing the cabins and painting the shell in 7 days. Due to the adoption of technologies such as nonredundant jointing and total station theodolite, the docking construction efficient was greatly improved. The assembly clearance fits process standard, and the maximum deviation precision of the installed bulbous bow was controlled within 5 millimeters. The outer plate weld inspection of non-destructive flaw detection and pressure completion has been approved by shipowner and inspection in the progress and quality.

The bulbous bow modification project has accumulated valuable experience for the following vessels, cultivated new technical talents, broken through the technical bottleneck of our company in bulbous bow prefabrication project, and filled the technology gap in our company.